Micromechanisms of the electro-plastic effect in magnesium alloys investigated by means of electron microscopy

Topic

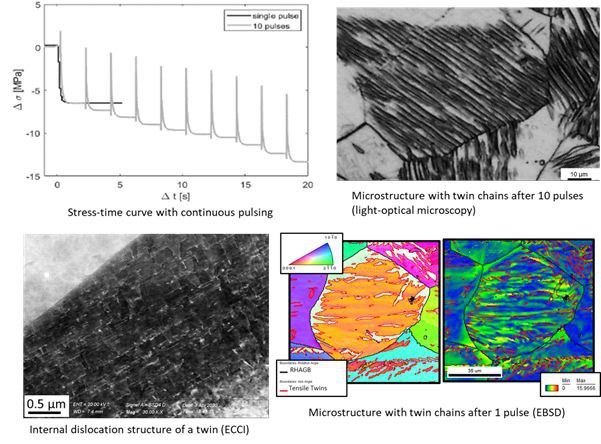

Aim of the project „Micromechanisms of the electro-plastic effect in magnesium alloys and other metals with hexagonal crystal structure investigated by means of electron microscopy“ is to establish whether an electroplastic effect (EPE) exists and to understand the physical mechanisms behind it. The EPE refers to an increase of ductility of a metallic material under the presence of a high-density electric current (103…104 Amm-2) flowing through the material during a forming process by other effects than just macroscopic Joule heating. As such high electric currents heat up the material very rapidly, the electric current is only applied in very short pulses with durations in the order of milliseconds. There are a number of theories to explain the EPE, including the effect of electron wind on dislocation movement, the very rapid deformation by a magnetic pinch effect, or the locallized Joule heating and consequent mobilisation of crystal lattice defects like dislocations and grain boundaries.

In the present project the EPE is investigated on metals and alloys with hexagonal crystal structure that are intrinsically more brittle than metals with cubic crystal structures and potentially show a high EPE. Particularly magnesium and its alloys was selected for its rather high brittleness and high potential as light structural material. This material, however, is difficult to investigate for a number of reasons, including its low strength and low electron scattering potential. Therefore further metals, namely Ti and Zn were added into the investigations. Ti has a significantly higher strength but its deformation behaviour is very comparable to Mg, Zn has a much larger c/a –ratio compared to Mg and Ti and therefore shows a different deformation behaviour.

The electroplastic experiments are carried out on macroscopic samples using a special device that allows to supply the required current densities. The device can be used to create single pulses or continuous pulses while deforming a sample. Height, duration and frequency of the pulses are well-controlled.

The microstructural investigations are mainly performed by SEM-based techniques, namely electron backscatter diffraction, EBSD, and electron channelling contrast imaging, ECCI, on bulk samples. Both techniques allow, due to their large probing areas, to observe even subtle changes of deformation structures and to perform before-after studies. We quantitatively analyse the kind and amount of activated slip and twinning systems, and the appearance of grain boundary sliding. Furthermore, also local grain boundary decohesion may be investigated in order to obtain information on the grain boundary strength in situations with and without electric pulses.

Collaboration with groups working on theory of crystal plasticity (Dr. Roters, MPIE) will be established in order to better understand which kind of physical effects might be responsible for the experimental observations, e.g. grain boundary strength versus change of critical resolved shear stresses of different slip systems.

Contact person(s)

Dr. Gregory Gerstein | Dr. Stefan Zaefferer |

|---|---|

Leibniz University of Hannover Institute of Material Science | Max-Planck Institut für Eisenforschung |

An der Universität 2 30823 Garbsen | Max-Planck-Str. 1 40237 Düsseldorf |

Tel: (+49) 511 762 3907 | Tel: (+49) 211 6792 803 |

Fax: (+49) 211 6792 333 | |

Proj.-Nr. GE 2673/3-2 | Proj.-Nr. ZA 278/9-2 |