Flash sintering of Perovskites

Topic

In this project we anticipate to use ferroelectric perovskite ceramics to further investigate the processes involved in flash sintering.

A range of properties / effects are hoped to be identified: The nature of charge carriers during the flash event, the internal sintering stresses, recombination of charge carriers, and the effects and the distribution of internal mechanical stresses will be investigated. As techniques in situ impedance spectroscopy, optical microscopy in the visible and IR-ranges, dilatometry, and optical interferometry as well as ex situ scanning force microscopy will be employed. The macroscopic characterization of dielectric, piezoelectric and ferroelectric properties will complement this research.

Additionally, the parameters and the appearance of the flash event itself are subject to manipulation: Further insights into the roles of the composition of the electrodes and the electronic carriers such as a change of the work function of the electric contacts, the use of a specific sintering atmosphere (oxidizing/reducing), and a change in the availability of electronic carriers will be investigated.

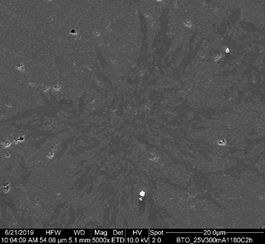

Barium titanate is the main material of choice for this project as it is a well-known, well-studied ferroelectric perovskite with a wide range of industrial applications. We have already observed flash-sintering in disk-shaped samples rather then the conventional bone-geometry, further manipulation of geometry and size will not only be useful for theory, but will also suggest practical routes for commercial application.

A further goal of the project is to investigate the possibility of flash sintering in magnetoelectric BaTiO3/CoFe2O4 composites as well as the effect on the aforementioned parameters by the addition of a second phase with a largely different conductivity. We assume that CoFe2O4 will trigger flash sintering in BaTiO3 and lower the sintering temperature even further.

Contact person(s)

Prof. Dr. Doru C. Lupascu |

|---|

University of Duisburg-Essen Institute of Material Science |

Universitätsstraße 15 45141 Essen |

Tel: (+49) 201 183 2689 |

Proj.-Nr. LU 729/25-1 |