Pattern Formation during Current Sintering

Topic

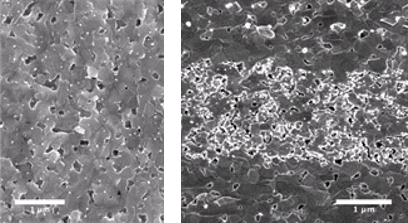

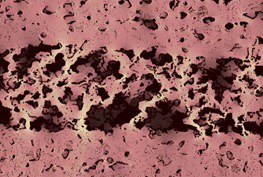

The microstructural evolution during current sintering is investigated experimentally and theoretically for the case that the conductivity drops locally due to a reaction-diffusion process induced by the current. Aluminum-doped ZnO serves as a paradigm for this class of transport processes with negative feedback. The self-organized patterns that emerge due to this mechanism are being analyzed in dependence of the process parameters for thin films as well as for bulk samples. The possibility of manipulating the pattern formation e.g. by applying the current as a pulse sequence or by external cooling are explored. Potentially they will allow control of the micro-structure on length scales larger than grain or pore size in the green body.

Experimental VS. Simulation research (aluminum: Zinc oxide)

Contact person(s)

Prof. Dr. Markus Winterer | Prof. Dr. Dietrich Wolf |

|---|---|

University of Duisburg-Essen | University of Duisburg-Essen Department of Engineering Sciences- Nanoparticle Process Technology |

Lotharstraße 1 47057 Duisburg | Lotharstraße 1 47057 Duisburg |

Tel: (+49) 203 379 4446 | Tel: (+49) 203 379 3327 or 2816 |

Fax: (+49) 203 379 4453 | Fax: (+49) 203 379 1681 |

Proj.-Nr. WI 981/16-1 | Proj.-Nr. WO 577/13-1 |